VIBRATION ANALYSIS IN NASHVILLE, TN

The cornerstone of Predictive Maintenance is vibration based machinery monitoring, and is generally the first technology utilized by most facilities. Vibration Analysis and temperature trending, when applied routinely and systematically to rotating machinery, will produce significant savings.

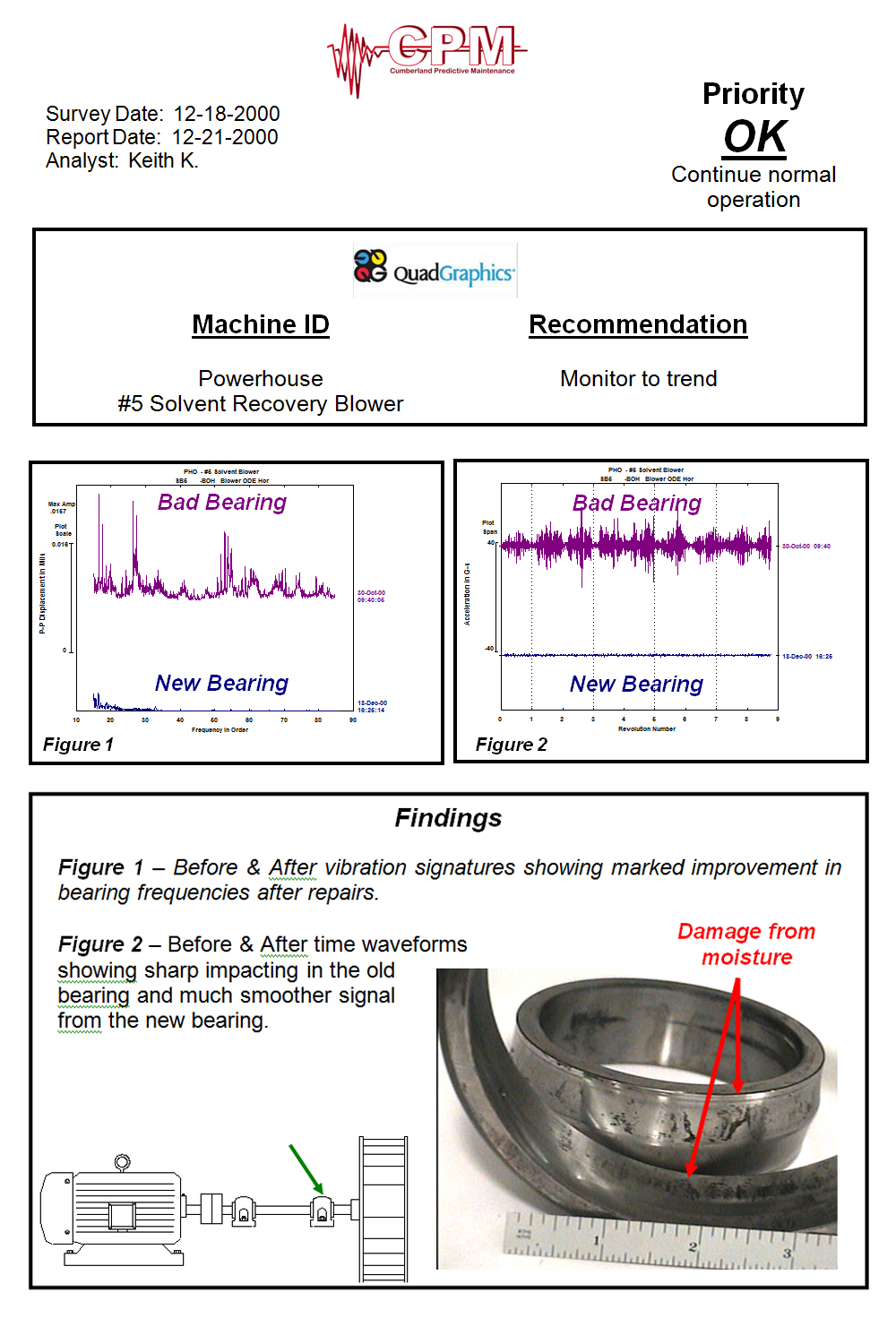

CPM can monitor an entire plant, an individual line or a single machine. Our technicians can quickly collect vibration and temperature data without interrupting normal plant operations. This data is then downloaded and analyzed using spectrum/waveform analysis, machinery specific information and historical trends.

Recommended actions are then assigned as follows:

Serious – Immediate attention

Moderate – Schedule repair

Slight – Possible fault, continue to monitor

OK – Continue normal operation

Problems detected with Vibration Analysis